|

|

#6---440 Stage 2 Dyno test S. Fehr

584 HP & 586 ft-lbs | 12/4/2021

David Hughes |

|

This is a dyno test of a 440 engine that is basically our Stage II build-up. The main differences are that the customer supplied some of his parts that he wanted us to use. This caused some problems and additional expenses, which we will point out. This is the reason we do not like to quote jobs like this. Never the less the project was extremely successful.

Block work:

The customer's well-raced 440 block was cleaned, deburred, crack checked, sonic tested. It was ok, and we square-decked it, line honed and bored and honed it +.060" with a torque plate. We used ARP main studs and head bolts. Piston choice were Keith Blacks "modified" for the proper cylinder pressure and quench. The Sealed Power piston rings were file fit so they would have the "proper" end gaps. The rods are a set of billet "H" beam rods that we now available, they have stock dimensions, full-floating wrist pins and are considerably stronger and lighter than factory rods.

The crank assembly was installed with Federal Mogul 1/2 groove main bearings, tri-metal rod bearings and cam bearings. Other components were brass freeze plugs and bronze distributor drive shaft bushing.

Camshaft choice was one of our larger, flat tappet hydraulic grinds, which was degreed-in. We then used a set of our custom length pushrods to achieve correct rocker arm/pushrod geometry. Degreeing in the camshaft was simplified with our premium quality, Pro Gear timing set which also offers longer life over standard sets and 3 key way "performance" timing sets.

The remainder of short block was assembled with our 6 quart oil pan, matching pickup and our high volume oil pump. A modified Mopar Performance windage tray completed the oil system assembly. Since the car will run in the 10's and would require SFI approved pieces, we used a Cyco damper and SFI flexplate.

|

|

| Description |

Part

Number |

| ARP main stud |

ARP 140-5401

|

| ARP head bolts |

ARP 145-3606

|

| Keith Black pistons |

KBP KB236.STD

|

| Connecting rods |

EAG CRS6760C3D

|

| Main bearings |

SEA 4924MA |

| Rod bearings |

SEA 2320CP

|

| Cam bearings |

SEA 1453M |

| Hydraulic camshaft |

HE4854BL |

| Racing hydraulic lifters |

HUG 5003 |

| Custom length pushrods |

5496 |

| Pro Gear timing set |

HUG 6434 |

| 6 quart racing oil pan |

MOP-P4529884 |

| Oil pump pickup |

MOP P4529567

|

| HV oil pump |

MEL M63HV |

| Windage tray |

MOP P4120998 |

| Pro Race damper |

PRP 64279 |

| SFI approved flexplate |

BMM 10236 |

|

Cylinder heads and top end:

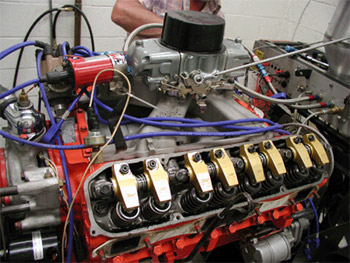

The heads are the latest version of our Stage II HP porting which features more mid-lift flow and about the same at maximum lift. The heads feature 2.14" intakes and 1.81" exhausts, both featuring 11/32" stems. The heads were modified for the proper quench and cylinder pressure. The customer was in love with his Crane 1.5:1 roller rockers so we used them. They required our billet steel hold downs and billet steel rocker spacer kit along with lots of setup time to properly locate and tighten them up on new shafts. The money he could have saved from this extra labor would have bought him a set of our 1.6:1 rockers and more power. This is again a case of spending more by trying to salvage old parts.

The intake was a used Edelbrock TM7 that we modified in the plenum and ports. Overall it worked out very well. We thought a Performer RPM might be better, too bad we didn't have time to test it. I think the modified Torker II would be hard to beat for this application, but we will keep on trying. The customer insisted on using his Street Demon 750 cfm carburetor for the dyno testing.

One good item the customer provided was a set of the famous Stahl headers. These 8 year old pipes had 2" primaries and were in excellent condition. The Stahl headers not only look different than the competition, they sound different, and sound better.

In our shop we always have a "power pool" when we test new or different combinations. The guesses ran from 532 to 563 HP and from 545 to 585 ft-lbs torque, the general consensus was that any power gain from the new heads would be offset by the small carburetor.

The camshaft was broken-in on the dyno with the outer valve springs only (like the instructions said) for about 30 minutes. Then the inner springs were installed with the help of our on-head spring compressor, making a pain-in-the-butt job a lot easier.

|

| Description |

Part

Number |

| 2.14" intake valve |

HUG 1018

|

| 1.81" exhaust valves |

HUG 1024S |

| Valve springs |

HUG 1107 |

| Chromoly retainers |

HUG 1203 |

| Machined valve locks |

HUG 1322

|

| Billet rocker hold-downs |

HUG 7442 |

| Billet steel rocker spacers |

|

| BB 1.6:1 Aluminum rockers |

1512-16 |

| Edelbrock TM7 Intake |

|

| On-head valve spring compressor |

PFM 67461

|

|

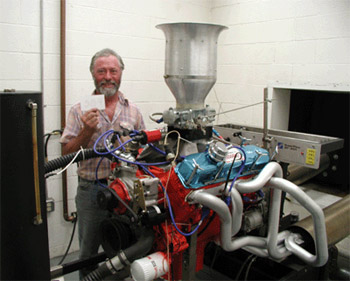

A happy customer holding his card for 584 HP |

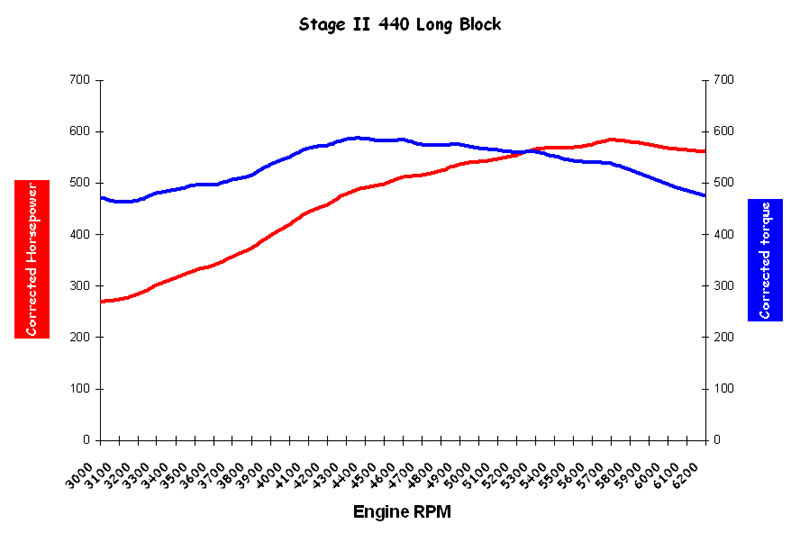

Dyno pulls and conclusion:

Then first pulls on the dyno are to check the jetting and timing to make sure the thing isn't carried home in a basket. The first checkout pull was only up to 4500 RPM, the timing was at a safe 30 total and the jetting a rich 88 primary, 89 secondary. We got a corrected 531 HP and 565 ft-lbs torque. There was a mad scramble to adjust pull numbers, this sucker was an animal! And it was reading "too lean".

We played with jetting and tried a pull to 5500 RPM, 563 HP and 574 ft-lbs torque. We have another 500 to 700 RPM to go and the spark is 4 less than ideal, we haven't played with carburetor spacers and the guys are getting quiet. I know what they are thinking, but no one wants to say anything fearing that it can't do it and they don't want to jinx it if it can ("it" being 600 HP). A combination of carburetor spacers were tried and we were up to 584 HP and 586 ft-lbs torque, still at 30 timing. We tried 28 and the power dropped to 571 HP. Then a funny thing happened, we ran out of gas. The gas was the customers' job and he had been instructed to get our usual AMOCO premium, listed on the pump at 93 octane. The problem is he only got 5 gallons. Now with 600 HP seemingly in reach he rushed out to quickly get more gas before this spell of good fortune disappeared. Our time on the dyno was running out and it was looking like we might only get a coupe more pulls in. He soon returned and we were back to 581 HP and only 545 ft-lbs torque, but the knock sensor was flashing, this had not happened until now. We backed the timing down to 28 583 HP and still spark knock, down to 26, 576 HP and still knocking, the torque was disappearing too. It must be a bad batch of gas, and no time to try some other station.

Dyno time ran out, and we didn't see 600 HP. During the time we were taking the engine off of the dyno the customer admitted he was in a hurry to get the refill and had purchased fuel at the first pump he could find. This first pump turned out to be a local blend that has 10% or more ethanol in it. I did not know whether to kill him or cry. Actually, the test was very successful I just hate leaving 15-20 HP or more in the gas tank. For an engine that was expected to have 565 HP and ended up with 20 HP more with the spark 4 retarded we should be very happy, and we were...sort of. From now on the customer can't "help", even if it is just to get gas.

Click here to see a larger view of the dyno chart

Note: At 5900 RPM with 584 HP the engine was pulling 1.5" inches of vacuum, so the carburetor was a little too small! This engine combination is currently available in long block form, and a kit form will be available soon. Keep an eye on the web page for updates.

|

|

|

| | Home | Phone: 309-745-9558 | Email: information@hughesengines.com |