October 2013

I’m In Love with, or, How We Built a Gen 3 Hemi

Yes, we have read all the tech articles and information about the Gen 3 Hemi’s and they certainly look good, but until you build one and test it yourself, you’re not a big fan. This is a modern technology engine designed with computer aided technology, known as finite element design. Unlike the more common engines we deal with, like the S.B. and B.B. engines, there is no metal, cast iron, or aluminum used to “maybe help” strengthen the block or the heads. The computer tells the designers exactly where support or strength is needed or not. So what you end up with is a very light, very strong design. But if you are used to looking at the older block and head design, you are still a little skeptical. This WAS our view of this engine. We had ported heads; sold cams and stroker kits forever but never built one up and dynoed it ourselves.

A longtime customer of ours, Zach Borman, talked us into building one for his race-only Dart. His basic idea was a 6.1 Hemi stroked to 426” with 5.7 Hemi heads, hydraulic roller cam, single 4 barrel carb. Then he threw us a ringer by adding the stipulation that this should run on pump gas.

We started with a new 6.1 block and a custom built stroker kit. From there we added a set of early 5.7 heads with our C.N.C.porting, one of our Hughes hydraulic cams, a Ritter 4 barrel intake, TTI 2” headers, a 950 cfm Holley, and a MSD electronic ignition system. Although we build a lot of pump gas engines, we were a little concerned about the compression ratio and the power expectations that Zach had of 680-690 HP. 680 HP from CI = 1.6 HP per cubic inch, that is like an 800 HP, 500 CI on pump gas—Oh yeah, that should be easy! Anyway, we race prepped the block, CNC’d the 5:7 heads, added larger valves and did some extra work. We then installed our 264º/268º @ .050”cam with the stock lifters & prepped rocker arms. And then we got to the Ritter intake manifold…..

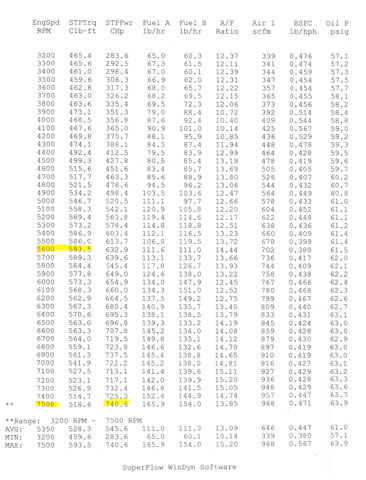

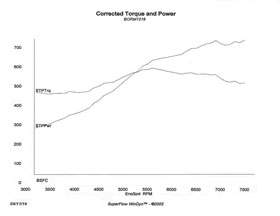

We port and test a lot of heads (it gets addictive) and intake manifolds. Generally, when you bolt an intake onto ported heads, you expect to lose25 to 45+ CFM due to the longer runners and design of the ports, etc. Well, with this Ritter “Hi-Ram” style intake P/N HUG5420, we only lost 10-12 CFM—Things are looking good. Maybe 680 HP won’t be as difficult to reach as we thought. The MSD electronic ignition system (P/N 6013 controller, 82558 coils and 8886 harness) really had me screwed up. I had no place to connect my timing light and my feeler gauge is useless with no points to set. However, Ben and Craig came to my rescue with a laptop that takes place of the timing lite, advance curve weights and springs, and my feeler gauge. And to say this system is too cool doesn’t cover it. I’m always concerned with initial startup on a fresh engine and without a distributor to time I was lost. Again, Ben and Craig assured me this would not be a problem. And it wasn’t. The engine fired immediately and every time we needed to start it. One of the first things we noticed is how smooth and “comfortable” the engine felt. Us old guys kind of get a feel for how an engine sounds, and some sound more comfortable. The MSD electronic ignition system was a breeze to adjust. This system would really show its value on a street engine. The advance curve can be varied up or down throughout the RPM range. Although not as useful on a race engine with a high stall converter, this could be very helpful on a street car. We used a set or TTI 2” headers for a Hemi in a Dart p/n TTI64L. We had to modify our set to fit in the dyno, but they are sweet. As the dyno sheet shows (see below), the 680/690 HP goal was easily exceeded with pulls showing high 730’s and a couple of times touched 740 HP. This engine has 13:1 compression ratio and the power curves between using 110 octane race gas a BP 93 octane pump were virtually identical—it must be those dual plug Hemi heads! The test shown was with a 950 CFM carb and 50% 93 BR pump gas and 50% 115 octane Sunoco fuel.

Assembly Tips:

· The Manley double roller chain assembly P/N 73205 made cam degreasing a breeze. We highly recommend it.

· The heads were our P/N 4609 with 2.100 int. and 1.575 exh Manley valves and fully CNC ported.

· We used our 1122 Beehive valve springs and showed no signs of lifter pump-up

· We built custom push rods from Smith brothers material

· The stroker was a Molnar technologies crank and rods with custom Diamond pistons

· 6qt Mildon oil pan and windage tray

· ARP head bolts and main studs

· Stanke rocker girdle and collars

· MSD 6-hemi ignition controller 6.1H -6013

· MSD HVC2 blaster coils 5.7 Hemi -82558

· MSD wiring harness -88864

· Cometic head gasket

· Meziere water pump

· Meziere mounting plate

· Passenger car timing cover

· Misc bolts and studs ARP

Afterthoughts:

The max power was made with 950 CFM Holley carb. We did not have much time to work on this carb or the 1050 dominator but the mixtures were not what we would have liked. With some carb tuning and collector tuning, I would think 750 HP possible and 600 lbs/ft or torque with this basic combination.

Dave Hughes

------------------------------------------------------------------------------

CLICK ON EITHER CHART BELOW TO VIEW ENLARGED VERSION

|